YES, AIR IS FREE BUT NOT FOR EVERYONE!

Whilst fresh air is free, air under pressure or compressed air is not. The compressed air distribution network is all too often a cause of leaks and load losses. The actual cost of compressed air therefore depends directly on the type of distribution circuit.

Increased compressed air costs

Although the compressor acts as the real motor in the assembly, in reality it is generally not this item which is the most expensive. Other essential factors must be taken into account when drawing up an objective analysis of the network: – air quality – required working pressure – type of network – air losses – choice of material. Apart from poorly designed networks requiring more powerful compressors, air leaks are all too often present throughout the system and in some cases can absorb nearly 50% of the compressor’s production, wasting both energy and money. But is this tolerable? On an older network, leaks or the like are in abundance. After a time, the compressor becomes out of breath and is replaced with a more powerful one. Do you believe that this is the correct way to solve this problem without effectively dealing with the causes?

Productivity and savings

Productivity and savings

To obtain the optimum efficiency from a network, apart from the ultra-fast assembly aspect, four criteria are absolutely essential:

- Intelligent and suited design: low or even zero load loss

- Perfect sealing: no leaks

- Clean air with constant quality: protected tooling

- No corrosion: longevity and maintenance savings.

Stolen money?

For your company and those of your customers, productivity gains are a constant concern. Under these conditions, each factor involved in the correct running and operating quality of the company must be taken into account, with the utmost thoroughness. However, there is one factor in many production facilities which is all too often neglected since it is invisible. In fact, just as invisible as air itself – compressed air.

This essential driving force behind various manufacturing steps in the most diverse sectors of activity is quite troublesome and very costly if not closely monitored. A poorly designed, poorly suited or old compressed air distribution circuit may therefore invisibly but unavoidably steal the so carefully acquired productivity gains. Money, your money and your customers’ money may be stolen in the most cunning way ever!

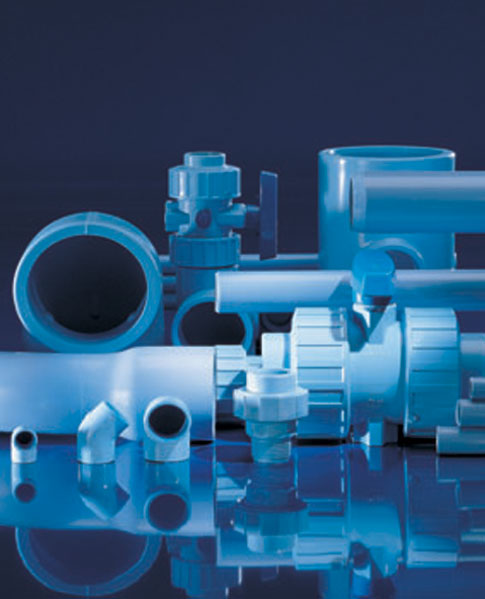

- Operating conditions:

- nominal pressure of 12.5 bars

- temperature -20°C to + 25°C

- simple and quick to install

- incomparable longevity

- reduced maintenance

- technical reliability

- absolute sealing

- light weight, easy to handle

- always clean air

- immediate identification

- totally corrosion free

GIRAIR®: THE QUALITY REPOSNSE TO NEW COMPRESSORS

SAFER air tightness + clean air + impact resistance

MORE RELIABLE anti-corrosion + self-extinguishing

MORE PRACTICAL quick installation + minimum maintenance + immediate identification

GIRAIR®: YOUR SOLUTION FOR COMPRESSED AIR!

GIRAIR® always more, always better!