EQOAIR – DISTRIBUTE THE AIR TO THE CONSUMER IN THE RIGHT WAY

Compressed air is an important factor in any production. It can make up to 50% of the total energy consumption in the industry, if it is not used rationally and does not eliminate hidden costs.

If the air is distributed wisely to the consumer it can save you money.

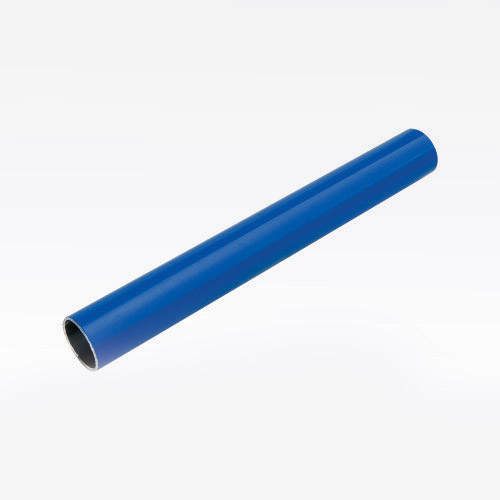

If we look at compressed air systems from the point of view of energy efficiency, we can conclude that, in addition to properly dimensioned equipment and adequate compressed air treatment, smart and quality compressed air distribution plays an equally important role in the pneumatic system. Also, we can say that it is a very important segment in the construction of compressed air and the time spent on the installation. These include operations such as cutting, processing, welding, painting, procurement of equipment for high-altitude work, various other types of special tools and the like. In addition to the above, an important factor is the financial investment, ie the cost of installation. These are all factors that affect the total value of investments and construction of compressed air pipelines, ie. air distribution to the consumer. Aluminum piping is an excellent investment because in industrial processes it makes savings provided by reduced pressure drop and elimination of leaks with the help of connecting elements that connect perfectly.

When you have a dilemma – ALWAYS CHOOSE PROFIT FOR THE LONG PATH

Compressed air distribution as an important factor in the pneumatic system