STEPEN is privately owned enterprise, founded in 1992 for the purpose of becoming a successful family business in sphere of construction industry. From its very foundation the enterprise STEPEN has developed dynamically, following modern technologies. Years of installation work are behind us, via which we have acquired knowledge and experience, which gives us that small yet very important edge when compared to other companies. With an offer of top quality equipment and highest level of service, we can safely say that we are one of the leaders on the market.

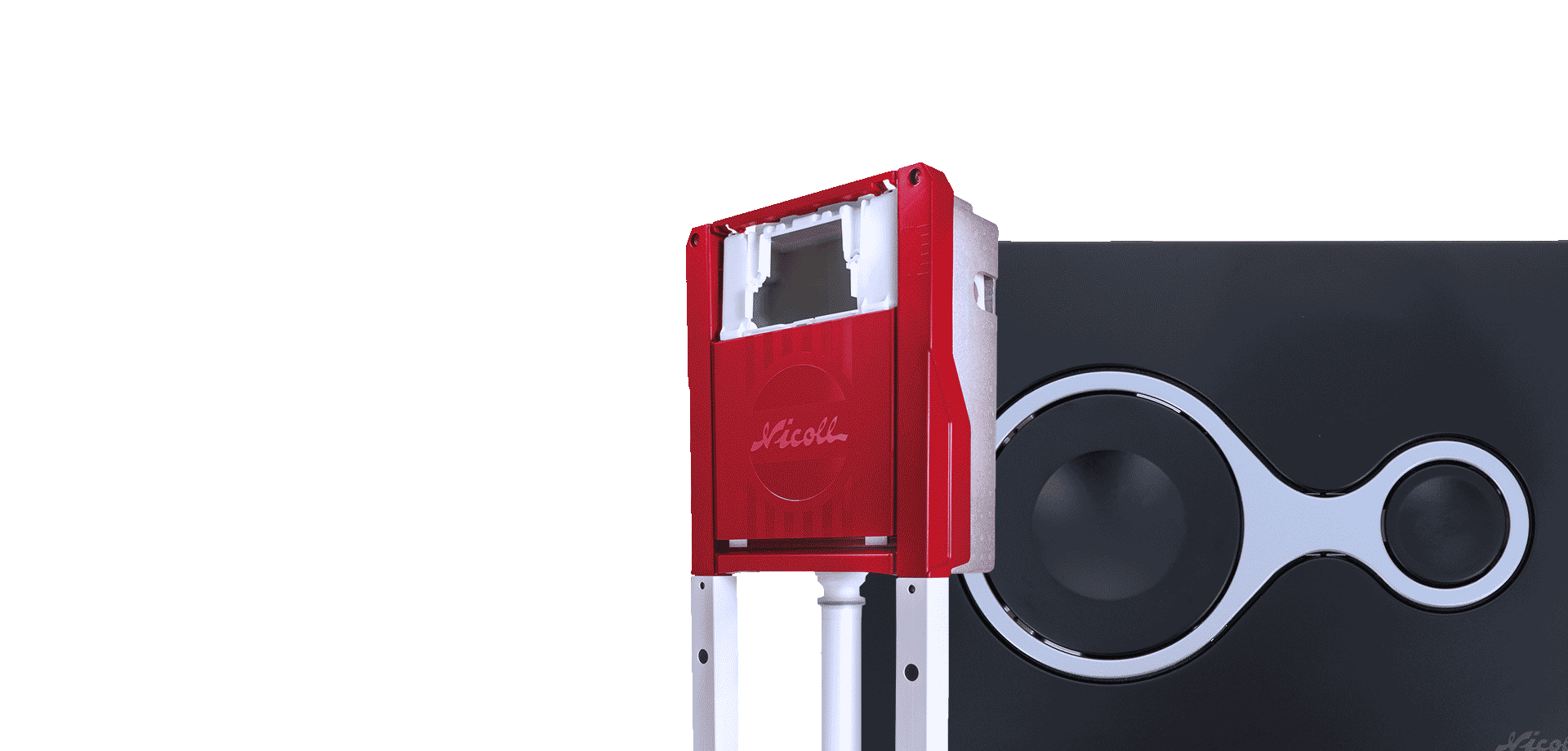

NICOLL Happy Support built-in cistern

Happy Support built-in cistern with unique innovative technical solutions for easy and quick installation. The first 2-block built-in cistern: quick, easy and safe installation. Unique sliding and rotary connection to the sewer: fast, simple and secure connection. Access to the cistern system through 2 openings: fast, simple and secure connection. The power connection is located in the cistern: there is no risk of water leakage. Polymer-reinforced cistern tank combined with a low-noise filling valve and bell with a patented silent closing and telescopic overflow system. Large selection of buttons, connection to the cistern system on the cable: quick, easy and secure connection. Precise and high quality system for quick and easy height adjustment. Product tested for loads of 400kg. Optimized packaging: for easier transport and work on site.